Application of warm-edge spacer in insulating glass

Fanyu

Chinamirrormanufacturer. com

2017-09-25 13:52:59

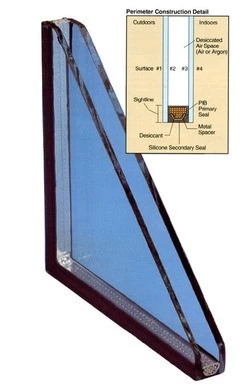

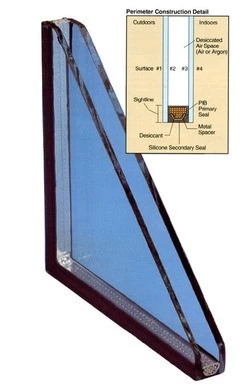

The energy-saving effect of insulating glass is much better than that of single layer glass. Influence of insulating glass insulation effect of three elements of thermal radiation, thermal convection and heat conduction, thermal radiation is the largest, therefore, to improve the energy-saving role of insulating glass, it is necessary to grasp the main contradiction, if not in these three areas together, then, The first is the need to use low radiation glass, the second is to consider filling the inert gas and warm edge spacer. In addition, we choose the different equipment insulating glass materials, we must make the substitution of the role to be improved from the whole, more can not appear to replace the conflict between the data, the role of the phenomenon, the third, the selection of insulating glass materials, Should consider the life of the hollow glass and windows to match the service life, four, also need to be satisfied with the cost-effective products, the use of wide-scale, easy to implement.

In ensuring that the existingInsulating GlassBasic function, the overall function has improved. Instead of losing some of the necessary functionality for the purpose of acquiring a function. At present, the use of warm edges mainly include extrusion molding PVC distance bar, silicone (or EPDM) spacer, Stainless steel spacer (0. $number, 0.13-0.15mm wall thickness), The plastic steel is composed of spacer bar, U-shaped steel spacer, compound rubber strip and break heat spacing bar. Among them, some warm edge aluminum spacer can reduce the edge of the hollow glass condensation phenomenon, but it is to reduce the sealing life of insulating glass at the cost; and the Heat insulation bar is upvc (medical improvement grade) and stainless steel (edible grade) Perfect combination, in achieving the perfect air tightness at the same time to achieve a more excellent insulation performance!

In ensuring that the existingInsulating GlassBasic function, the overall function has improved. Instead of losing some of the necessary functionality for the purpose of acquiring a function. At present, the use of warm edges mainly include extrusion molding PVC distance bar, silicone (or EPDM) spacer, Stainless steel spacer (0. $number, 0.13-0.15mm wall thickness), The plastic steel is composed of spacer bar, U-shaped steel spacer, compound rubber strip and break heat spacing bar. Among them, some warm edge aluminum spacer can reduce the edge of the hollow glass condensation phenomenon, but it is to reduce the sealing life of insulating glass at the cost; and the Heat insulation bar is upvc (medical improvement grade) and stainless steel (edible grade) Perfect combination, in achieving the perfect air tightness at the same time to achieve a more excellent insulation performance!