Glass fences its aesthetics, cleanliness, safety, and love for the people, the following small glass enclosure construction process give you a brief introduction.

Construction technology for glass railing installation

First, construction preparation:

1, check Member sizes;

2, review the installation part of the railing sizes;

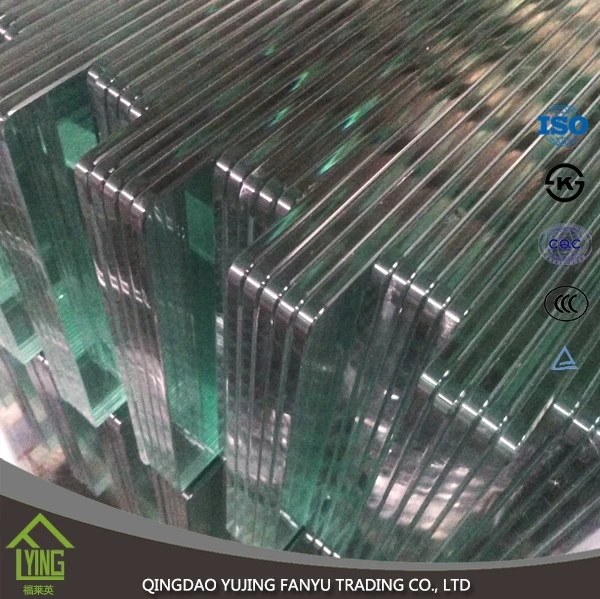

Loft 3, glass, glass machining dimension and process drawings;

4, check the electricity meets the job requirements;

5, combination of semi-finished products

Second, the installation process

1, the process flow:

Protection → preparation of semi-finished products → → → line → positioning drilling anchors → railing installation installation installation → reviews → adjust → → → → glass installation fastening fastening sealant → → → clean glue line pressing, calendering → remove residual sealant and the whole bar hygiene → finished product protection

2, the main method:

① According to design drawings should be first of all building balcony size deviation measurements, according to survey results, determine railing installation base.

② standard as a benchmark, according to the drawing grid lines on the balcony on the beam and mark;

③ check the positioning is correct, according to the drawing requirements for drilling anchor bolt installation

④ field in place install, review and adjustment;

⑤ When the steps, there should be two operations, one person holding the steel frame, the size of another person under proofing, when you are sure, bolted the party.

⑥ glass prior to installation, must be preinstalled, should be in place, temporary fix, then cable adjustment fixed;

Sadly, glass after installation, seal position using toluene for cleaning, spray cleaning should be especially careful not to let the solution to places outside of the joint, clean gauze smear should be replaced to ensure the cleaning effect, and finally with a dry, clean gauze will wipe away traces of the solvent evaporation, keep the sealing surface dry;

⑧ injection should be uniform, dense, full, also note that sizing methods and avoid waste;

After Krispy Kreme, injection plastic, synthetic resin adhesive seam should be shoveled along the direction of injection pressure, scrape off excess glue and rubber sewn into the design shape, smooth, smooth plastic joints;

Third, the quality should be paid attention

1, prohibit the use of metal cleaning tools, sand, metal shavings adhering tool shall not be used;

2, semi-finished and finished products should be required to pile up, safe and reliable, and arrange custody;

Four, semi-finished products and finished products protection

1, fabrication and installation process, special attention should be gently, no bumps, scratches, Twining for plastic film application processed steel protected and dimensioned and used parts;

2, strengthening protection of semi-finished and finished products, maintain contact with the general contractor, protect installed railings from scratch;

3, quality inspector and security staff should be closely and take measures to improve the protection of semi-finished and finished products;

4, recommends that the general contractor in the near isolation of installed glass balustrades are easy to install the railings (simple steel erection isolation) to avoid construction personnel on intentional or unintentional damage to glass.

Five, construction safety

1 strictly abide by relevant engineering construction safety management regulations, and project supervision and inspection of security at all times, taking the necessary safety precautions in the construction process, eliminate potential accidents;

2, access to the construction site had to wear a helmet, and consciously protect the safety products;

3, with the project Department of the tertiary education of workers, non-illegal command, illegal operations.