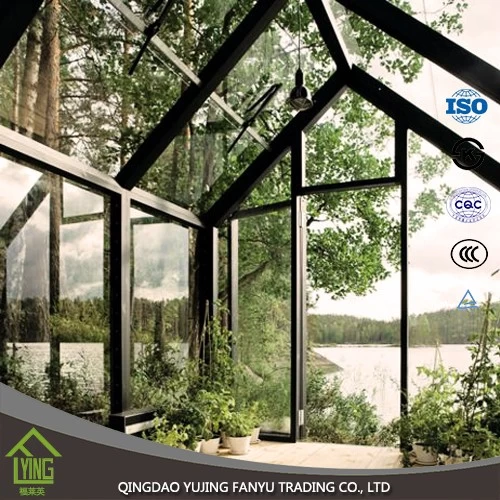

Coated glass

fanyumaoyi

chinamirrormanufacturer.com

2017-03-03 14:14:59

| Coated glass is coated on the surface of the glass layer or multi-layer films of metals, alloys and metal compounds to alter the optical properties of the glass to meet a particular requirement. Coated glassAccording to the different product characteristics, can be divided into the following categories: heat-reflective glass, low-e glass (low-e), conductive film glass and so on. Hot reflection glass General is in glass surface plating a layer or multilayer such as chrome, and titanium or stainless steel, metal or its compounds composition of film, makes products is rich of color, for visible has appropriate of transmission rate, on infrared has high of reflection rate, on UV has high absorption rate, so, also called sun control glass, main for building and glass curtain wall; low radiation glass is in glass surface plating by more layer silver, and copper or Tin, metal or its compounds composition of film Department, products on visible has high of transmission rate, Infrared has a high reflectivity, has good insulating properties, mainly used in buildings and cars, ships and other means of transport, due to the strength of the film is bad, generally made of insulating glass; conductive film glass is coated with conductive indium tin oxide thin films on glass surface, can be used for glass heating, defrosting, mist, as well as liquid crystal displays, and so on; Coated glass production methods, mainly in vacuum magnetron sputtering, vacuum evaporation, chemical vapor deposition, sol-gel method. Magnetron sputtering coating glass using magnetron sputtering technology to design and manufacture multilayer complex films, can be plated on glass substrate with white many colors, the better corrosion resistance and wear resistance properties of the coating, which is one of the production and use of products. Vacuum evaporation coating glass variety and quality compared with magnetron sputtering coating glass, there are gaps, has gradually been replaced by vacuum-sputtering. Chemical vapor deposition is in on the float glass production line into the decomposition of reaction gas in the hot glass surface, evenly deposited on the glass surface coated glass. This method is less equipment investment, easy control, low cost, good chemical stability, thermal processing, is one of the most promising methods of production. Production of coated glass by sol-gel process is simple, stability or deficiencies is the product too high light transmittance, less decoration. Coated glass is the most widely used in heat-reflective glass and low-e glass. Vacuum magnetron sputtering and chemical vapor deposition method of two kinds of production. Internationally famous vacuum magnetron sputtering equipment manufacturer BOC has the United States company and the German company of LEYBOLD, the famous manufacturer of chemical vapor deposition with British company Pilkington.  |