Introduction to Photoelectron Glass

Fanyu

www. glass. com. cn

2017-10-13 15:29:50

Dimming glass was invented and patented by researchers at Kent State University in the late 80. At home, people are accustomed to say dimming glass for intelligent electronic control dimming glass, intelligent glass, liquid crystal glass, electronic control glass, chromotropic glass, pdlc glass, smart glass, magic glass and other names.

Material properties and characteristics of dimming glass

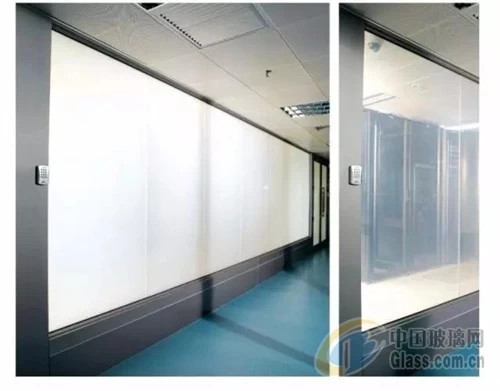

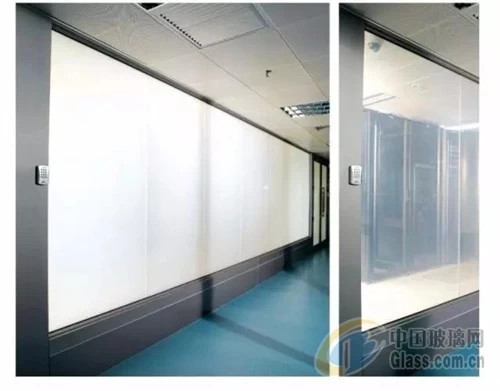

Dimming glass itself not only has the characteristics of safety glass, but also has the control of glass transparent or not privacy protection function, because of the characteristics of glass film interlayer, dimming glass can also be used as a projection screen, instead of the ordinary curtain, on the glass to render high-definition picture image.

1. Privacy protection function: The biggest function of the intelligent dimming glass is the privacy protection function, can control the transparent opaque state of glass at any time.

2. Projection function: Intelligent dimming glass or a very good projection hard screen, in the light suitable environment, if the selection of high lumen projector, projection imaging effect is very clear outstanding.

3. With the advantages of safety glass, including the safety of debris splash after rupture, good resistance to strike strength.

4. Environmental characteristics: Dimming glass in the middle of the dimming film and film can be insulated, blocking more than 99% of ultraviolet light and more than 98% of infrared. Shielding part of infrared radiation to reduce heat and transmission. and shielding ultraviolet radiation, can protect the interior furnishings not because of ultraviolet radiation and the appearance of fading, aging and other conditions, protect personnel from direct ultraviolet radiation caused by diseases.

5. Noise characteristics: Dimming glass in the middle of the dimming film and film has a sound damping effect. can partially block noise.

Dimming glass is a laminated glass, is sandwiched between two layers of liquid crystal film, commonly known as dimming film, liquid crystal film, liquid crystal film by en membrane covered in the most central, high-temperature molding.

Processing and production technology of dimming glass

A total of three kinds of processing methods are as follows: 1. One-Step vacuum molding, 2. Using autoclave processing method, 3. Water bath method.

1. One-Step vacuum molding method: Its equipment structure is simple, but really can make dimming glass equipment, its processing technology seems simple, but in the actual operation of the temperature control accuracy of the request is very high, will appear the waste phenomenon is bubble, open, fog degree.

2. Autoclave processing method: The former process of autoclave processing is similar to that of one-step processing, in the late stage, high pressure autoclave molding. Autoclave processing can effectively avoid bubbles, open and other phenomena, but the disadvantage of dimming glass finished product performance and service life greatly shortened.

3. Water Bath Method: The sealing fixture immersed in 100 degrees of the sink, is the most accurate and homogeneous processing temperature, but the fixture is very difficult to manufacture, at present only Japanese manufacturers to adopt.

Construction and installation node of dimming glass

1. First in the installation of dimming glass, according to the building structure to make the installation of glass around the frame.

Introduction to Photoelectron Glass

In the middle part of the upper groove of the frame, the glass width is drilled φ15mm-φ20mm to the top gate at half the size. If you install more than one piece of glass, half of the width of each piece of glass in the upper groove of the site need to drill. Each export wire is a pair of preset conductors, the wire diameter is φ0.5mm, the length is 2.5m, the box body reserved 300mm, the ceiling from the hole to the frame body or put the line to the place of the control box.

The frame must be made to ensure that the glass is installed on a plane and perpendicular to the ground. The inner wall of the frame is bonded with rubber strips around the edge mouth.

2. The installation of dimming glass should be noted to install a fixed piece, that is, the fixed upper gear block.

The installation of a number of dimming glass, the need to adjust glass in the gap between the glass 3-5mm, glass clearance overall consistent.

Connect each piece of glass power cord to the power control box. Fixed up and down the block, the file block in the glass wall contact should be bonded to the rubber strip. Install the Fixed power control box, block each piece of glass, and then carry out the whole joint test. Outer decoration of frame body. The glass is closed with clearance.

Dimming Glass Price range

Dimming glass price is relatively high, just when the advent of tens of thousands of dollars per square meter to the current per square metre less than million yuan, but because of high costs and other reasons, dimming glass prices have been relatively high, which also determines the application of the field more positioning in the high-end market.

Material properties and characteristics of dimming glass

Dimming glass itself not only has the characteristics of safety glass, but also has the control of glass transparent or not privacy protection function, because of the characteristics of glass film interlayer, dimming glass can also be used as a projection screen, instead of the ordinary curtain, on the glass to render high-definition picture image.

1. Privacy protection function: The biggest function of the intelligent dimming glass is the privacy protection function, can control the transparent opaque state of glass at any time.

2. Projection function: Intelligent dimming glass or a very good projection hard screen, in the light suitable environment, if the selection of high lumen projector, projection imaging effect is very clear outstanding.

3. With the advantages of safety glass, including the safety of debris splash after rupture, good resistance to strike strength.

4. Environmental characteristics: Dimming glass in the middle of the dimming film and film can be insulated, blocking more than 99% of ultraviolet light and more than 98% of infrared. Shielding part of infrared radiation to reduce heat and transmission. and shielding ultraviolet radiation, can protect the interior furnishings not because of ultraviolet radiation and the appearance of fading, aging and other conditions, protect personnel from direct ultraviolet radiation caused by diseases.

5. Noise characteristics: Dimming glass in the middle of the dimming film and film has a sound damping effect. can partially block noise.

Dimming glass is a laminated glass, is sandwiched between two layers of liquid crystal film, commonly known as dimming film, liquid crystal film, liquid crystal film by en membrane covered in the most central, high-temperature molding.

Processing and production technology of dimming glass

A total of three kinds of processing methods are as follows: 1. One-Step vacuum molding, 2. Using autoclave processing method, 3. Water bath method.

1. One-Step vacuum molding method: Its equipment structure is simple, but really can make dimming glass equipment, its processing technology seems simple, but in the actual operation of the temperature control accuracy of the request is very high, will appear the waste phenomenon is bubble, open, fog degree.

2. Autoclave processing method: The former process of autoclave processing is similar to that of one-step processing, in the late stage, high pressure autoclave molding. Autoclave processing can effectively avoid bubbles, open and other phenomena, but the disadvantage of dimming glass finished product performance and service life greatly shortened.

3. Water Bath Method: The sealing fixture immersed in 100 degrees of the sink, is the most accurate and homogeneous processing temperature, but the fixture is very difficult to manufacture, at present only Japanese manufacturers to adopt.

Construction and installation node of dimming glass

1. First in the installation of dimming glass, according to the building structure to make the installation of glass around the frame.

Introduction to Photoelectron Glass

In the middle part of the upper groove of the frame, the glass width is drilled φ15mm-φ20mm to the top gate at half the size. If you install more than one piece of glass, half of the width of each piece of glass in the upper groove of the site need to drill. Each export wire is a pair of preset conductors, the wire diameter is φ0.5mm, the length is 2.5m, the box body reserved 300mm, the ceiling from the hole to the frame body or put the line to the place of the control box.

The frame must be made to ensure that the glass is installed on a plane and perpendicular to the ground. The inner wall of the frame is bonded with rubber strips around the edge mouth.

2. The installation of dimming glass should be noted to install a fixed piece, that is, the fixed upper gear block.

The installation of a number of dimming glass, the need to adjust glass in the gap between the glass 3-5mm, glass clearance overall consistent.

Connect each piece of glass power cord to the power control box. Fixed up and down the block, the file block in the glass wall contact should be bonded to the rubber strip. Install the Fixed power control box, block each piece of glass, and then carry out the whole joint test. Outer decoration of frame body. The glass is closed with clearance.

Dimming Glass Price range

Dimming glass price is relatively high, just when the advent of tens of thousands of dollars per square meter to the current per square metre less than million yuan, but because of high costs and other reasons, dimming glass prices have been relatively high, which also determines the application of the field more positioning in the high-end market.