Application of industrial robot in glass processing equipment

Fanyu

Chinamirrormanufacturer.com

2017-11-17 15:19:21

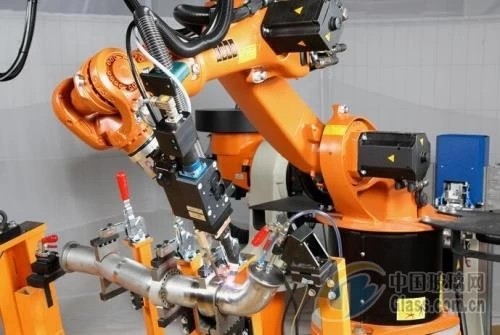

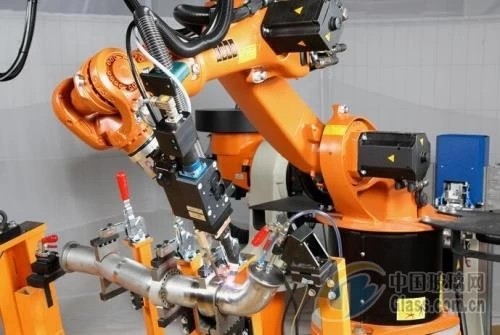

Concerned about the great convenience brought by the development of science and technology to the industrial production, the adoption of scientific and technological means to meet the actual product quality and production efficiency needs of industrial production, but also to the safety of industrial production workers to bring good protection. In this paper, in the actual work of glass processing equipment in the application of industrial robots in-depth research and analysis, hope that in the future work process to achieve the specific work of quality management.

Application of industrial robot in glass processing equipment

First of all, should aim at the specific robot application situation to carry on the analysis, should establish a robot control program system, and in the concrete work process carries on the robot function the concrete adjustment and the debugging, guarantees the robot in the glass processing industrial production process to have the good production effect, Upgrade the quality of glass products to meet the market economy to the production of industrial production efficiency upgrade demand.

Secondly, we should pay attention to the application of the industrial robot in the working process of the glass straight edge machine, and discuss the scientific and effective method of robot application through practice in the actual production work. In this paper, a robot carrying inspection system is set up to analyze the safety of the robot in the handling of glass products and to realize the application demand in the future work. Then, on the production platform of glass processing, we try to run the robot to carry the glass, and further realize the robot instead of the artificial target.

Through practical work can be found that industrial robots can take the way to remove the glass from the original location, and safe to the designated range of locations, to achieve the purpose of robot-assisted industrial production, improve production efficiency, reduce labor intensity, improve production safety.

Furthermore, in the process of glass processing and production, it is also necessary for the robot to participate in a more detailed working environment, so as to allow the robots to take part in the automatic feeding of glass straight edge machine. To test the quality and safety of robots involved in this work, it is necessary to establish an experimental platform.

In the concrete work process of the experimental platform, the parameter setting can be found that the specific drawing work path setting has the teaching result of setting point, summarizing the experience and lessons in the experiment, applying the scientific way to adjust in the future work, can better guarantee the smooth progress of the future work, Also can further enhance the actual quality and effect of industrial production.

The practice has proved that the application of Advanced robot working mode in the glass production process can improve the actual work efficiency and quality of production, meanwhile, it can reduce the strength of manpower labor, reduce the danger of personnel work, and promote the consciousness of safe production. The protection of workers at the same time led to the overall value of the economic benefits of industrial production.

Application of industrial robot in glass processing equipment

First of all, should aim at the specific robot application situation to carry on the analysis, should establish a robot control program system, and in the concrete work process carries on the robot function the concrete adjustment and the debugging, guarantees the robot in the glass processing industrial production process to have the good production effect, Upgrade the quality of glass products to meet the market economy to the production of industrial production efficiency upgrade demand.

Secondly, we should pay attention to the application of the industrial robot in the working process of the glass straight edge machine, and discuss the scientific and effective method of robot application through practice in the actual production work. In this paper, a robot carrying inspection system is set up to analyze the safety of the robot in the handling of glass products and to realize the application demand in the future work. Then, on the production platform of glass processing, we try to run the robot to carry the glass, and further realize the robot instead of the artificial target.

Through practical work can be found that industrial robots can take the way to remove the glass from the original location, and safe to the designated range of locations, to achieve the purpose of robot-assisted industrial production, improve production efficiency, reduce labor intensity, improve production safety.

Furthermore, in the process of glass processing and production, it is also necessary for the robot to participate in a more detailed working environment, so as to allow the robots to take part in the automatic feeding of glass straight edge machine. To test the quality and safety of robots involved in this work, it is necessary to establish an experimental platform.

In the concrete work process of the experimental platform, the parameter setting can be found that the specific drawing work path setting has the teaching result of setting point, summarizing the experience and lessons in the experiment, applying the scientific way to adjust in the future work, can better guarantee the smooth progress of the future work, Also can further enhance the actual quality and effect of industrial production.

The practice has proved that the application of Advanced robot working mode in the glass production process can improve the actual work efficiency and quality of production, meanwhile, it can reduce the strength of manpower labor, reduce the danger of personnel work, and promote the consciousness of safe production. The protection of workers at the same time led to the overall value of the economic benefits of industrial production.