The choice of raw materials for insulating glass

fanyumaoyi

chinamirrormanufacturer.com

2017-03-14 11:48:38

Empty glass from the 60 in China since its production experienced a double glass, a simple double-glass, hand sealant, double seals and newly developed composite rubber Strip type insulating glass. After nearly 40 years of development, the market has matured. Along with the emphasis on building energy efficiency, quality issues have been put on the agenda of the insulating glass.

Influencing factors of hollow glass quality are: (a) the selection of raw materials, (ii) manufacturing process. Here talk about the selection of raw materials for insulating glass. Raw material quality will directly affect the quality and service life of insulated glass.

Currently there are three main types of insulating glass: (a)-slot aluminum sealant, (ii)-slot aluminum double seal, (iii) composite sealing strip type insulating glass. -Slot aluminum sealant, because of its poorly sealed, moisture, condensation lead glass, frosted, short life, so the kinds of insulating glass is gradually phased out. Two kinds of raw materials for insulating glass are: glass, aluminum, gusseted, butyl rubber, two-part polysulfide rubber or silicone Tong gel, desiccant, seal Strip. Simple talk about the selection of raw materials for these.

, Glass selection:

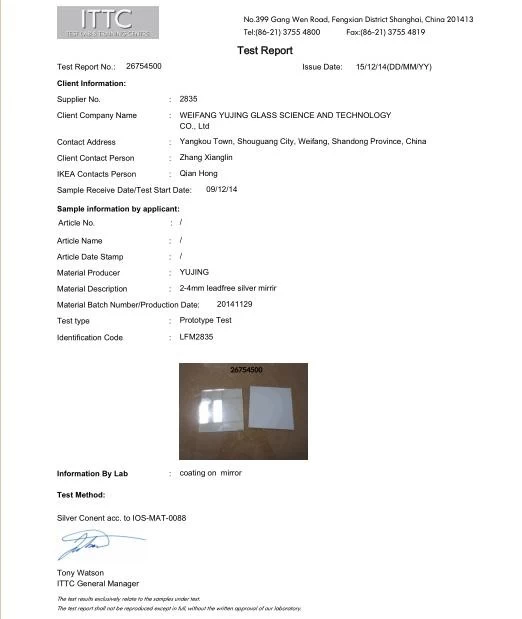

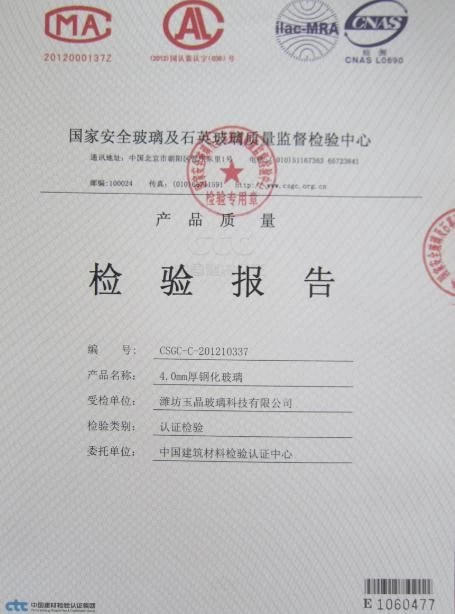

1, manufacture of raw glass insulating glass can be colourless float glass, coated glass,Tempered glass, Laminated glass, and so on. You should avoid using ordinary flat glass, ordinary flat glass are not up to the requirements of transparency and strength. Above the original glass plate must comply with the appropriate standard, qualified to use

2, different in various batches of glass before cutting the first check there is no color, color should be a larger glass, respectively, for different projects or different building facades.

3, glass cutting, should be implemented strictly according to the drawings, and operations personnel should pay attention to the glass surface may not have obvious defects such as scratch, bubbles.

Second, the selection of aluminum, gusseted

1, the thickness of the aluminum should be between 0.3-0.35mm, thickness should be uniform, vent holes evenly distributed. Aluminum Anodic oxidation treatment or decontamination must be bent, be sure to use good quality and high grade products. Raising the utilization ratio of aluminium.

2, gusseted to choose the right size, surface should be wiped clean.

Third, drier

Current use of insulating glass desiccant, there are three main types: 1, the absorptive capacity of the volatile well; 2, on the adsorption quantity of inert gases lowest; 3, General molecular sieve. Users should follow their own glue questions consult manufacturer, select the appropriate molecular sieves and zeolites also have suitable granularity (1-1.5mm) and hardness. In addition, using molecular sieve of the environment must be dry, fill the molecule should be within 1.5 hours of use, molecular sieves should be used in favor of nudity in order to ensure the quality of insulating glass.

Selection of four, sealants

1, butyl rubber:

Butyl rubber is the first aluminum type insulating glass seals, it is a hot-melt Adhesive, with low water vapor transmission rate (lowest in the insulating glass sealant) high viscosity, is shade between the aluminum sides and glass block the most effective barrier to water vapor, but it required a dedicated machine heating, pressing, extrusion coating on aluminum bars on both sides.

More domestic rubber manufacturers, but the production of rubber, the heating temperature and pressure are not the same, some manufacturers of butyl rubber or even with a machine, often interrupted due to impurities. This requires the user to select good quality products, and clear understanding of the requirements.

2, polysulfide rubber

Polysulfide rubber insulating glass sealant used is the largest one of polysulfide rubber has good oil resistance, refractoriness and tightness. Polysulfide rubber to metal oxide as a curing agent using aggregate, two-component ratio of approximately 1:10, proportion and the degree of influence on the effect of not too big, therefore glue machine can also hand painted.

Polysulfide rubber selection requirements: two-component difference of pattern; maturity of more than six months; strong UV resistance, good liquidity and curing elastic.

Cave 3, Silicon rubber

Chamber of Silicon sealant has a structural resistance, aging resistance and UV resistance, but its weakness is water vapor transmission rate high. Tong glue suitable for thus in strong light, bad places, such as glass curtain walls, must be sealed with butyl rubber the first road. Tong rubber silicon, in the past, my country's long dependence on imports is now leading group for State economic and Trade Commission has set up a Chamber of silicon glue, secure certification of structural adhesive. China Zhengzhou Zhongyuan, Guangzhou and other four have passed certification.

Five, composite sealing stripes

This is a sealing material developed in the 1980 of the 20th century by the American chemist. Strip collection supporting frame (wave-shaped aluminum Strip), seal (butyl rubber), dry (drying agent) in one of the raw materials for insulating glass. Its biggest advantage is the simple operation, less waste of raw materials, staff shortage, low management costs, operating environment. Disadvantage is the glue absorb moisture slowly, must have special equipment. Strip currently under production prices are higher, and selection of composite sealing stripes for, taking into account the smooth surface, strip quality, rubber content, viscosity, etc.

Influencing factors of hollow glass quality are: (a) the selection of raw materials, (ii) manufacturing process. Here talk about the selection of raw materials for insulating glass. Raw material quality will directly affect the quality and service life of insulated glass.

Currently there are three main types of insulating glass: (a)-slot aluminum sealant, (ii)-slot aluminum double seal, (iii) composite sealing strip type insulating glass. -Slot aluminum sealant, because of its poorly sealed, moisture, condensation lead glass, frosted, short life, so the kinds of insulating glass is gradually phased out. Two kinds of raw materials for insulating glass are: glass, aluminum, gusseted, butyl rubber, two-part polysulfide rubber or silicone Tong gel, desiccant, seal Strip. Simple talk about the selection of raw materials for these.

, Glass selection:

1, manufacture of raw glass insulating glass can be colourless float glass, coated glass,Tempered glass, Laminated glass, and so on. You should avoid using ordinary flat glass, ordinary flat glass are not up to the requirements of transparency and strength. Above the original glass plate must comply with the appropriate standard, qualified to use

2, different in various batches of glass before cutting the first check there is no color, color should be a larger glass, respectively, for different projects or different building facades.

3, glass cutting, should be implemented strictly according to the drawings, and operations personnel should pay attention to the glass surface may not have obvious defects such as scratch, bubbles.

Second, the selection of aluminum, gusseted

1, the thickness of the aluminum should be between 0.3-0.35mm, thickness should be uniform, vent holes evenly distributed. Aluminum Anodic oxidation treatment or decontamination must be bent, be sure to use good quality and high grade products. Raising the utilization ratio of aluminium.

2, gusseted to choose the right size, surface should be wiped clean.

Third, drier

Current use of insulating glass desiccant, there are three main types: 1, the absorptive capacity of the volatile well; 2, on the adsorption quantity of inert gases lowest; 3, General molecular sieve. Users should follow their own glue questions consult manufacturer, select the appropriate molecular sieves and zeolites also have suitable granularity (1-1.5mm) and hardness. In addition, using molecular sieve of the environment must be dry, fill the molecule should be within 1.5 hours of use, molecular sieves should be used in favor of nudity in order to ensure the quality of insulating glass.

Selection of four, sealants

1, butyl rubber:

Butyl rubber is the first aluminum type insulating glass seals, it is a hot-melt Adhesive, with low water vapor transmission rate (lowest in the insulating glass sealant) high viscosity, is shade between the aluminum sides and glass block the most effective barrier to water vapor, but it required a dedicated machine heating, pressing, extrusion coating on aluminum bars on both sides.

More domestic rubber manufacturers, but the production of rubber, the heating temperature and pressure are not the same, some manufacturers of butyl rubber or even with a machine, often interrupted due to impurities. This requires the user to select good quality products, and clear understanding of the requirements.

2, polysulfide rubber

Polysulfide rubber insulating glass sealant used is the largest one of polysulfide rubber has good oil resistance, refractoriness and tightness. Polysulfide rubber to metal oxide as a curing agent using aggregate, two-component ratio of approximately 1:10, proportion and the degree of influence on the effect of not too big, therefore glue machine can also hand painted.

Polysulfide rubber selection requirements: two-component difference of pattern; maturity of more than six months; strong UV resistance, good liquidity and curing elastic.

Cave 3, Silicon rubber

Chamber of Silicon sealant has a structural resistance, aging resistance and UV resistance, but its weakness is water vapor transmission rate high. Tong glue suitable for thus in strong light, bad places, such as glass curtain walls, must be sealed with butyl rubber the first road. Tong rubber silicon, in the past, my country's long dependence on imports is now leading group for State economic and Trade Commission has set up a Chamber of silicon glue, secure certification of structural adhesive. China Zhengzhou Zhongyuan, Guangzhou and other four have passed certification.

Five, composite sealing stripes

This is a sealing material developed in the 1980 of the 20th century by the American chemist. Strip collection supporting frame (wave-shaped aluminum Strip), seal (butyl rubber), dry (drying agent) in one of the raw materials for insulating glass. Its biggest advantage is the simple operation, less waste of raw materials, staff shortage, low management costs, operating environment. Disadvantage is the glue absorb moisture slowly, must have special equipment. Strip currently under production prices are higher, and selection of composite sealing stripes for, taking into account the smooth surface, strip quality, rubber content, viscosity, etc.