These five factors will determine the quality of insulating glass

Fanyu

Chinamirrormanufacturer.com

2018-05-03 15:08:36

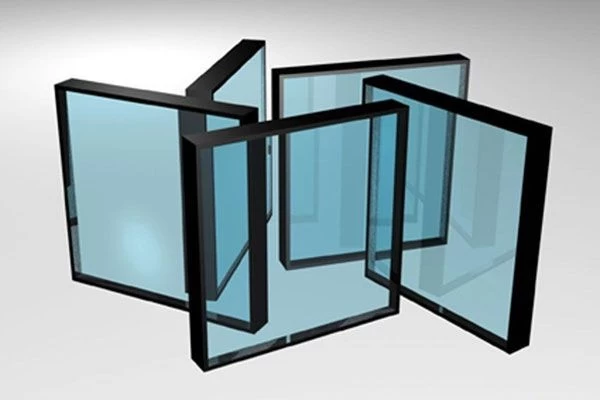

Since the use of hollow glass, its production has experienced the process of double glass, simple double glass, manual single-channel sealing, double-channel sealing and compound tape-type hollow glass that appeared in recent years. After nearly 40 years of development, the hollow glass market has gradually matured. With the emphasis on building energy conservation in China, the quality of insulating glass has been put on the agenda. How can we create high quality insulating glass?

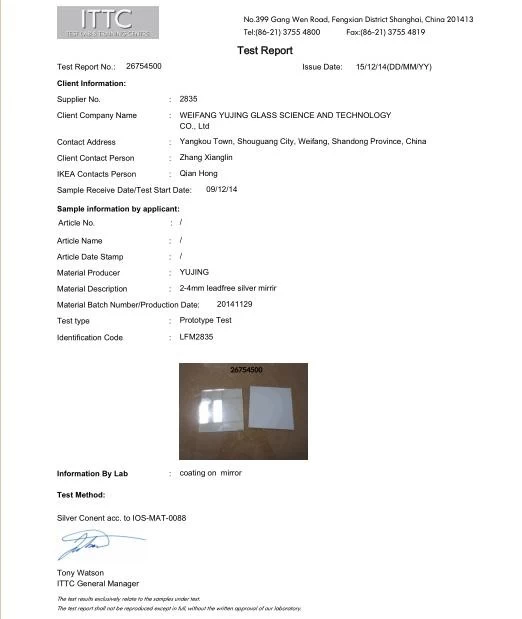

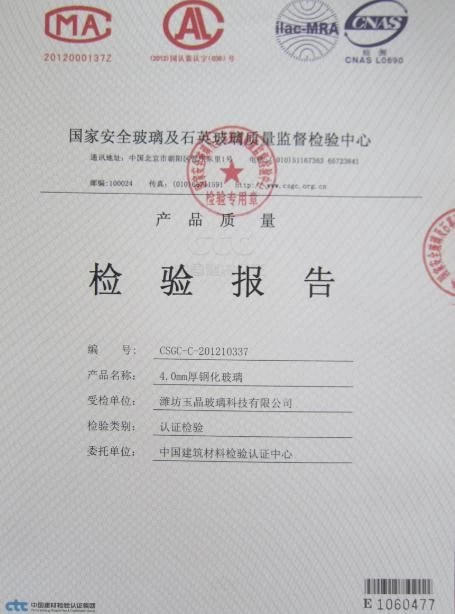

Former domesticInsulating glassThere are three main types: 1. Groove aluminum type single-channel seal; 2. Groove aluminum double-channel seal; 3. Composite sealant strip type hollow glass. The Groove aluminum single-channel seal, because of its poor sealing, easy to enter moisture, resulting in glass condensation, frost, short life, so the kind of hollow glass is gradually eliminated. The main raw materials of the latter two kinds of insulating glass are: glass, aluminum strips, gussets, butyl rubber, two-component polysulfide rubber or silicone rubber, desiccant, composite sealant strips. The Here's a quick summary of the five factors that affect the quality of insulating glass! The TheOne: Selection of the original glass The 1. The original glass for making insulating glass can be colorless float glass, coated glass, tempered glass, laminated glass, and the like. The use of ordinary flat glass should be avoided. The transparency and strength of ordinary flat glass do not meet the requirements. The above glass original film must meet the requirements of the corresponding standard, and can be used only after passing inspection. The 2, different manufacturers of different batches of glass first check whether there is color before cutting. The 3, glass cutting size, should be strictly enforced according to the requirements of the drawings, while the operator should pay attention to the glass surface, there must be no obvious defects such as scratches, bubbles. The TheII: Selection of aluminum strips and gussets The 1. The thickness of the aluminum strip should be between 0.3-0.35mm, the thickness should be uniform, and the vent holes should be evenly distributed. Aluminium strips must be anodized or decontaminated and must be bent. We must choose products with good quality and high quality. Improve the utilization of aluminum strips. The 2, the size of the insertion angle should be selected, the surface should be clean. The TheThree: The use of desiccants The At present, there are three types of desiccants for insulating glass: The 1, better absorption of volatiles; The 2, the adsorption of inert gas is very low; The 3, ordinary molecular sieves. The The user should select the appropriate molecular sieve according to his own needs, and the molecular sieve should have the appropriate particle size (1-1.5mm) and hardness. In addition, the environment in which molecular sieves are used should be dry and the packing molecules should be used within 1.5 hours to ensure the quality of the insulating glass. The TheFour: The selection of sealant The 1, butyl rubber: The Butyl rubber is the first seal of aluminum strip type insulating glass. It is a hot melt adhesive with a very low moisture vapor transmission rate (low in the hollow glass adhesive) with high viscosity. It is the side of the aluminum strip and A very effective barrier against water vapour between the glass, but it needs to be heated, pressurized, and extruded on both sides of the aluminum bar by a special machine. The At present, there are many domestic butyl rubber manufacturers, but the glue produced by each manufacturer is not the same as the heating temperature and pressure. Some manufacturers' butyl rubber can't even be coated with lacquer, often resulting in interruption due to impurities. This requires the user to select a good quality product and understand its usage requirements. |